Introduction

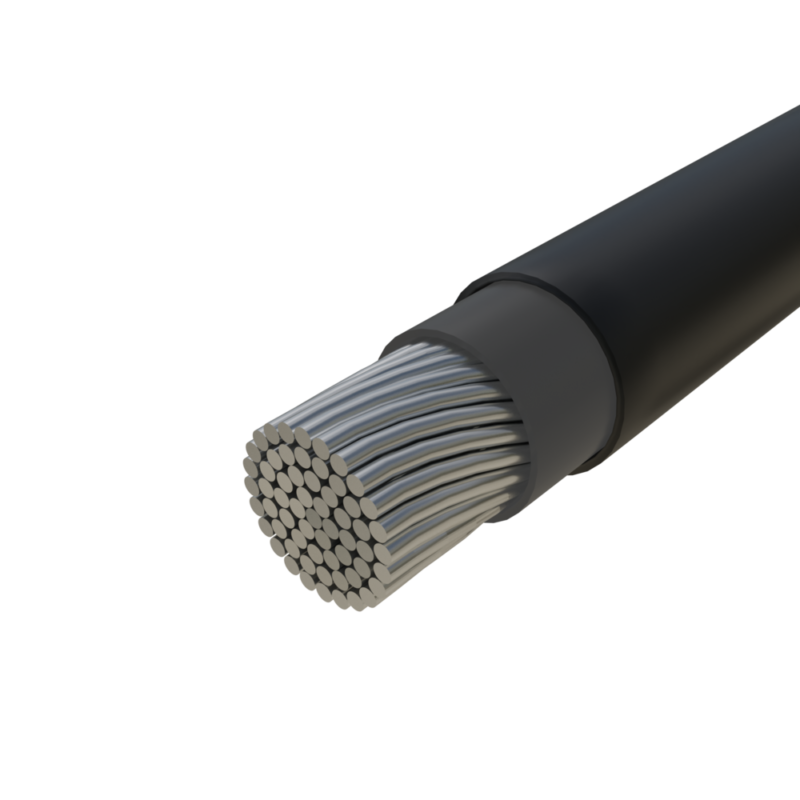

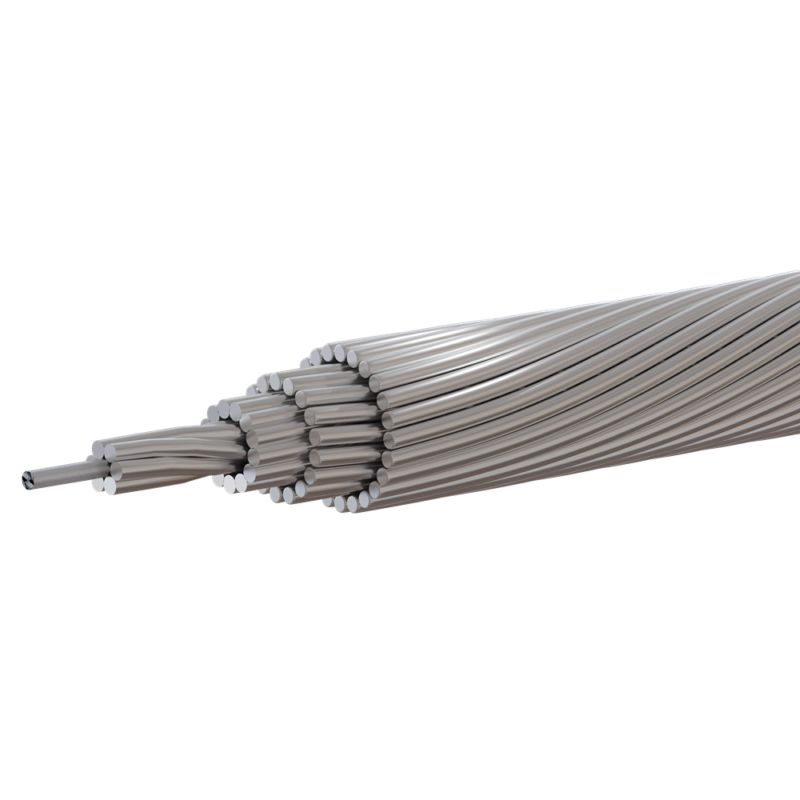

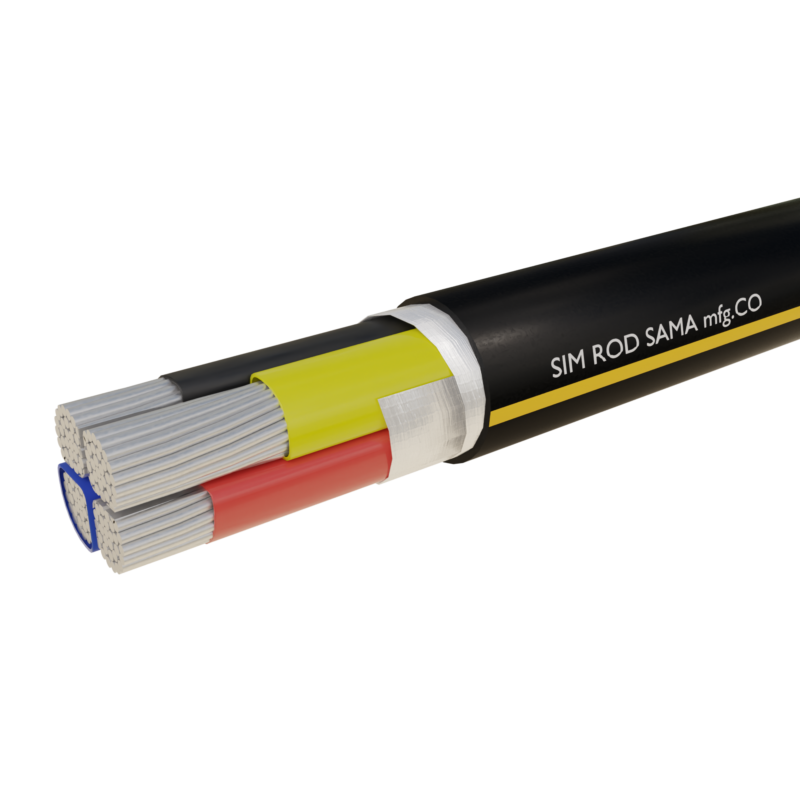

Concentric lay stranded Aluminium Alloy Conductors (AAAC) are made out of high strength Aluminium – Magnesium – Silicon Alloy. SIM ROD SAMA manufactures and supply AAAC with different variants of electrical grade alloy type 6101 and 6201.

These conductors are designed to get better strength to weight ratio and offer improved electrical properties, excellent sag-tension characteristics, and superior corrosion resistance when compared with ACSR. As compared to a conventional ACSR conductor, the lighter weight, comparable strength & current carrying capacity, lower electrical losses and superior corrosion resistance have given AAAC a wide acceptance in the distribution and medium & high voltage transmission lines.

Features

high strength to weight ratio

• better sag characteristics

• improved electrical properties

• excellent resistance to corrosion

Specifications

AAAC manufactured by SIM ROD SAMA meets or exceeds the requirements of all international standards like ASTM , AS , BS , CSA , DIN , IEC , NFC , SS – etc .

Complete Conductor

It is similar in construction and appearance to the AAC (all-aluminum conductor). The AAAC conductor is manufactured in accordance with the requirements of the latest issue of ASTM B399. The AAAC conductor is manufactured from a heat-treated, magnesium-silicide high strength 6201 T81 aluminum alloy. The aluminum strands consist of a concentric- stranded cable of 7, 19 , 37 or more wires. The sizes and standings listed are common examples used in overhead lines. Metric (mm) sizes are also available.

Benefits

• Aluminum alloy conductors have a number of advantages over the use of the ACSR or all- aluminum conductors.

• Lower power losses than for equivalent single- aluminum-layer ACSR conductors. (The inductive effect of the steel core in the ACSR is eliminated).

• Simpler fittings than those required for ACSR.

• Excellent corrosion resistance in environments conducive to galvanic corrosion in ACSR.

• Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

• Outside diameters are the same as for standard ACSR conductors, permitting interchangeability of fittings.

• Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

Applications

AAAC aluminum alloy conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.

SIM ROD SAMA can manufacture & supply AAAC on wooden / steel reels

Leave a Reply